The new Active Corrosion Protection system by Volvo Penta is an electronic anode system that replaces conventional zinc or magnesium sacrificial anodes.

Electrolytic action is corrosion that attacks metals. It will always attack the weakest base metal, when those metals are actually connected. So conventional anodes are made of weaker metals (normally zinc or magnesium, depending on whether the boat is in salt or brackish water) that bolt to the expensive bit you want to protect.

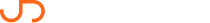

But wear rates vary considerably, sometimes within the same marina. Volvo Penta’s new system, which is designed to work with its outdrives, replaces conventional anodes by applying impressed currents through a transom unit, continually measuring and automatically adjusting the electrical output for ideal protection in both brackish and salt water.

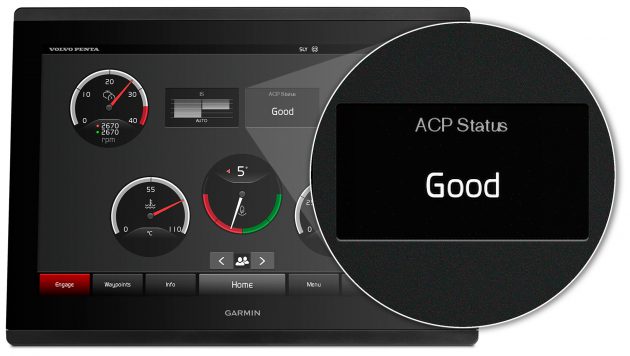

Available with new Volvo Penta outdrives, it is fully integrated into the boat’s Electronic Vessel Control (EVC), enabling owners to monitor the protection status from the helm. It is integrated into standard engine displays and can be retrofitted on Volvo Penta engines from 2007 with EVC generation C2-on.